How To Big Companies Think About Clean Energy

Photographer: Mikael Sjoberg/Bloomberg

At that place'south a Fortune to Be Made in the Obscure Metals Backside Clean Ability

The era-defining shift from fossil fuels to clean energy will deliver an unprecedented new boom for commodities—and an opportunity for investors—as a range of relatively obscure materials become essential to delivering emissions-complimentary power, transport and heavy manufacture.

The transition could crave as much as $173 trillion in free energy supply and infrastructure investment over the next 3 decades, according to research provider BloombergNEF, and volition reverberate from lithium-rich salt flats in Chile to polysilicon plants in China'south Xinjiang region.

As electric vehicles supercede gas guzzlers, and solar panels and air current turbines replace coal and oil as the world's almost important energy sources, metals like lithium, cobalt and rare earths are on the brink of rapidly accelerating demand, along with more than familiar industrial materials like steel and copper.

Primary Energy Supply by Source

*The New Free energy Outlook (NEO) is BloombergNEF's almanac long-term scenario assay on the time to come of the energy economic system. Light-green Scenario is a internet-zero pathway where green hydrogen complements greater electricity use, recycling and bioenergy.

Sources: International Free energy Agency, BloombergNEF

"The energy transition is driving the next commodity supercycle," said Jessica Fung, head strategist at Zug, Switzerland-based Pala Investments Ltd., which funds mining projects tied to decarbonization. "It is a decades-long transition, but the time to invest and make money is this decade. The time is now."

Prospects for technology manufacturers, metals producers and energy traders are immense, while regular investors are already benefiting. Numerous clean-energy stocks have more than doubled in value since the commencement of 2022, and the emergence of futures contracts for battery materials and a proliferation of initial public offerings in the sector volition extend options to gain exposure.

Though shifting demand patterns are being signposted far in advance, projection developers urgently need to secure uppercase for new mines or product lines. Efforts to lift supplies of cardinal raw materials—which can require years of exploration and structure—must begin now to continue pace with future requirements. That pressure could be most pronounced for EV charging infrastructure and lithium-ion batteries, which face steep growth curves, though more established solar and wind sectors have been challenged this year by pricier commodities.

Failing to act fast enough could fifty-fifty hazard an economic shock comparable to the oil crises of the 1970s, said Robert Johnston, an offshoot senior research scholar at the Center on Global Energy Policy at Columbia University in New York. Concerns about futurity bottlenecks are reflected in the eye-watering gains of some green stocks. "I don't run across an like shooting fish in a barrel solution because these supply chains don't magically announced overnight," he said.

Disquisitional Mineral Needs Beyond New Energy Technologies

*IEA assessed aluminum demand for electricity networks just; rare earths are used in electric motors, not in EV batteries.

Source: International Free energy Agency

By 2030, demand for cobalt, used in many battery types, will bound by about seventy%, while consumption of lithium and nickel past the battery sector volition be at least five times higher, according to BNEF. There'll be a demand for more than manganese, iron, phosphorus and graphite, while copper, needed in make clean energy technologies and to aggrandize electricity grids, will also exist a major beneficiary.

Four fundamental components of the energy transition—solar panels, wind turbines, lithium-ion batteries, and EV charging units—show the complexity of supply chains required to aid the world quit fossil fuels, and how the need for vast quantities of crucial metals should spur prices college.

•••

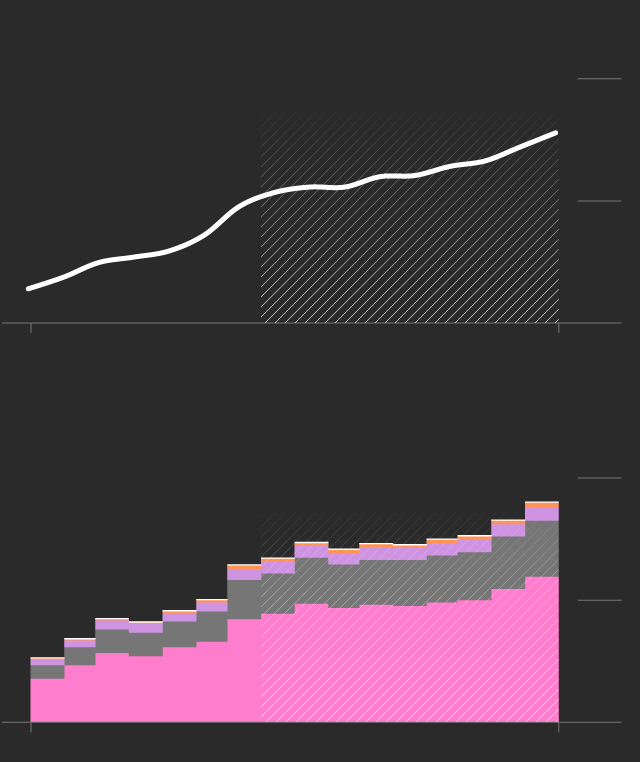

Solar Panels

KEY METALS AND MATERIALS:

Total solar gross capacity additions

Gigawatt

400

200

0

PROJECTED

2015

2030

Full demand for materials

Million metric tons

12

6

0

PROJECTED

2015

2030

Solar panels with the power capacity of a gigawatt demand most 18.v tons of silver, three,380 tons of polysilicon and 10,252 tons of aluminum, co-ordinate to BloombergNEF estimates.

An unexpected jump in demand for solar panels in late 2022 following Joe Biden'southward victory in the U.Southward. election and President Xi Jinping's vow that Cathay would get carbon neutral by 2060 defenseless producers off guard.

A surge in the price of polysilicon helped throw a decade of falling solar costs into reverse, threatening to ho-hum uptake just as several large governments were putting their weight backside it. Several new polysilicon plants, more often than not in Mainland china, are now existence built to try and continue up with demand.

That offers a foretaste of what could occur in the coming years if the supply of raw materials isn't sufficient.

Solar likewise offers an instance of how geopolitical mistake lines could hamper the energy transition. China currently dominates production of solar equipment and White House sanctions related to Beijing's declared treatment of the Uyghur indigenous grouping in Xinjiang are now threatening projects in the U.S.

•••

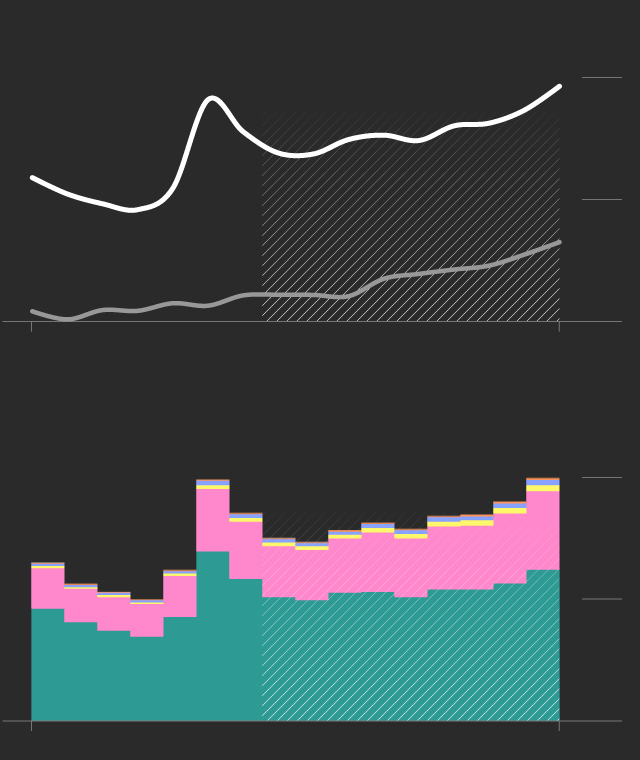

Wind Turbines

Primal METALS AND MATERIALS:

Glass fiber reinforced plastic

Carbon fiber reinforced polymers

Gross capacity additions by engineering

Gigawatt

100

Onshore

50

Offshore

0

PROJECTED

2015

2030

Materials demand

Million metric tons

lx

30

0

PROJECTED

2015

2030

Air current turbines and infrastructure with the power capacity of a gigawatt need virtually 387 tons of aluminum, 2,866 tons of copper and 154,352 tons of steel, co-ordinate to BloombergNEF estimates.

Ascension cost pressures have begun to touch on the scroll-out of wind projects, and the expiry of key subsidies in China ways capacity additions are forecast to drop this year from a record in 2022, according to the Global Air current Energy Council.

Denmark's Vestas Wind Systems A/South, one of the world'southward biggest turbine producers, has cutting its outlook for the remainder of 2022, citing ascent raw materials prices and disruptions to supply chains. Prices of steel—a vital ingredient for the skyscraper-sized towers—accept jumped in the U.South. this yr and also advanced in Cathay and Europe. Fifty-fifty as installations decline from concluding year'south loftier they'll remain stiff and surge once again to reach 129 gigawatts past 2030.

•••

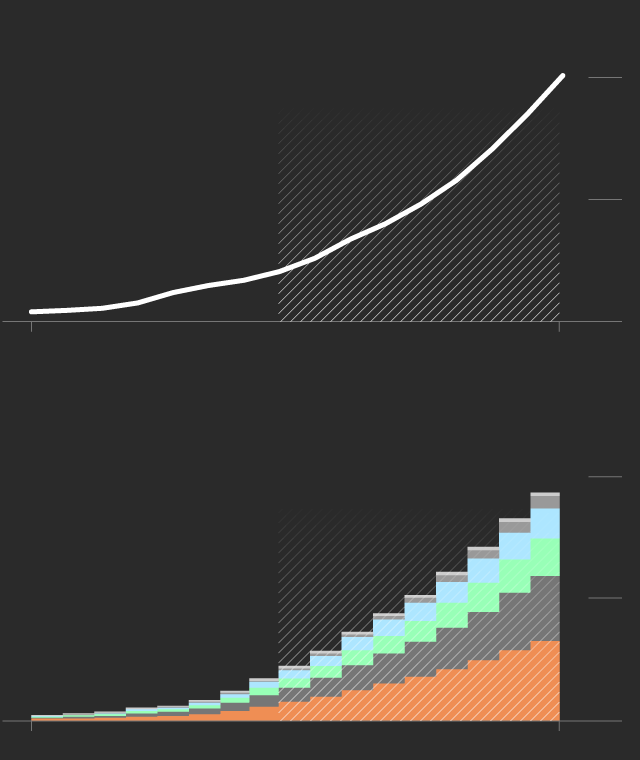

Lithium-Ion Batteries

KEY METALS AND MATERIALS:

Lithium-Ion battery need

2K

Gigawatt hours

1

0

PROJECTED

2014

2030

Total demand for materials

12

1000000 metric tons

6

0

PROJECTED

2014

2030

Lithium-ion batteries able to shop 1 gigawatt 60 minutes of energy require about 729 tons of lithium, one,202 tons of aluminum and i,731 tons of copper, co-ordinate to BloombergNEF estimates.

Supply of lithium raw materials will remain tight through 2022 every bit demand from the battery sector builds, BNEF said in a June study. Lithium hydroxide, the chemical favored for premium cells, could see shortages past 2027.

Limited availability of other materials is already threatening the battery sector'southward power to continue pace with the EV boom, said Yang Hongxin, general manager of SVolt Energy Applied science Co., which has an agreement to supply Jeep-maker Stellantis NV. Lithium chemicals and copper foil are a detail concern, while all key battery metals accept seen prices advance since mid-2020.

Battery ingredients nickel and manganese could see some of the most astringent shortages later this decade, said Kwasi Ampofo, head of metals and mining at BNEF. In that location'southward enough mined material, only a lack of capacity to process those metals into specialist chemicals could pose problems, he said.

Price swings are a bigger business organisation in the battery sector because EVs are still budgeted cost parity with combustion engine vehicles and higher costs could have an effect on adoption, said Daniel Quiggin, a senior research fellow focused on free energy, environment and resources at London's Chatham Business firm.

•••

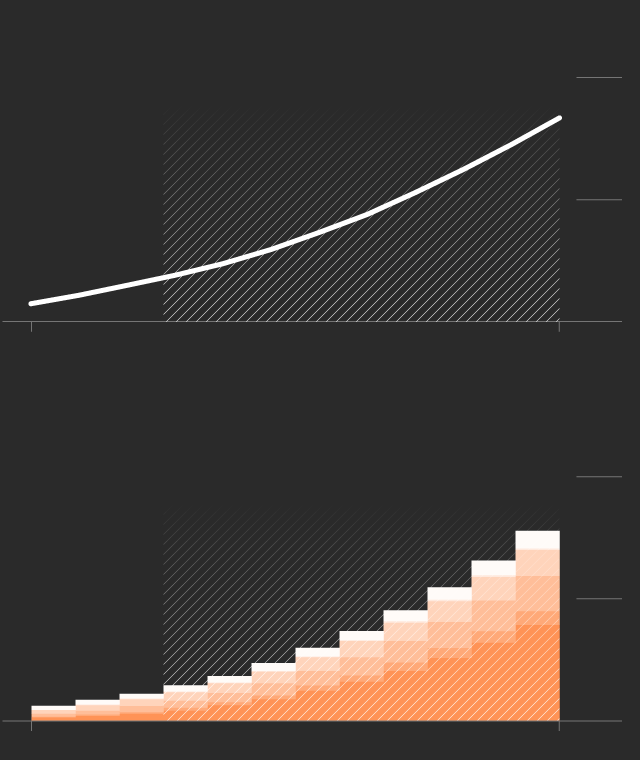

EV Chargers

Public charging outlets high EVO

1000000 charging outlets

12

6

0

PROJECTED

2019

2030

Total demand for copper

Thousand metric tons

400

200

0

PROJECTED

2019

2030

A fast, public electric vehicle charger typically needs 25 kilograms of copper, while a smaller charger to utilize at home needs effectually 2 kilograms of copper, according to BloombergNEF estimates.

Automakers run across EV charging units as cardinal to convincing motorists to ditch combustion engines, yet manufacturers tasked with delivering the hardware are being squeezed by cost increases and a global shipping crunch.

Installations of public chargers—along highways, in grocery shop parking lots or at fleet depots—jumped more than a third terminal year to bring the global full to 1.36 one thousand thousand nozzles. Today's cost pressures pale in comparison to what might happen later this decade, with copper demand for chargers predicted past BNEF to surge.

Charger installations are set to increase quickly to reach 309 million connectors by 2040, when the sector's almanac investment volition top $590 billion.

EV charging infrastructure could be most exposed to raw fabric shortages, BNEF's Ampofo said. China—which has more public connectors than the rest of the world combined—is adding chargers at a breakneck footstep, while the latest U.Southward. infrastructure programme allocated spending in that direction and companies including Tesla Inc. and BP Plc have made large commitments, he said.

•••

As the free energy transition supercycle gets closer, a major question is whether miners, financiers and governments can mobilize enough capital fast enough to bring on new supplies in line with demand. That means raw materials and the companies that produce them should offer college returns—though also more gamble—than component manufacturers, equipment makers or electric car producers, co-ordinate to Pala's Fung.

"Information technology doesn't thing what battery chemistry you lot accept, lithium is needed across all of them, and nickel is needed in many of them," she said. "If it's solar or wind or EV charging units, you need copper to connect information technology all together—that's why we like looking at these commodities."

The globe's biggest mining firms, including BHP Group and Glencore Plc, are emphasizing their links to clean energy, while smaller competitors are surging. Lithium producers including Pilbara Minerals Ltd. and Orocobre Ltd. are advancing faster this year than battery giants like Contemporary Amperex Technology Co. and are among the summit performers in the Bloomberg Electric Vehicles Total Return Index.

Still, green-focused equities have stumbled earlier. Valuations of solar equipment makers plunged from a 2007 meridian, and lithium miners suffered more than two years of losses through early 2022 before resuming gains.

Investors need to advisedly fourth dimension moves to add together exposure to the free energy transition theme, said Camille Simeon, a Sydney-based investment managing director at Aberdeen Standard Investments, which manages global avails worth about $635 billion. They should also be prepared for cyclical price swings that affect nigh all bolt, and exist wary of frothy valuations.

"Information technology's very clear that demand is accelerating for the raw materials that become into those products," she said. "You likewise need to consider, considering we are talking such a long-dated timeframe, how plausible and realistic is that, and how much do you want to pay for that at this indicate in time?"

More On Bloomberg

Source: https://www.bloomberg.com/graphics/2021-materials-silver-to-lithium-worth-big-money-in-clean-energy/

Posted by: hughtitheivelt.blogspot.com

0 Response to "How To Big Companies Think About Clean Energy"

Post a Comment